Our M-Tronic technology is designed to make sure that your tool delivers an optimum performance, all day, every day, by making automatic adjustments to regulate the fuel and air mix to the machine.

However, there are a couple of instances where you may need to reset your M-Tronic machine. Firstly, if you carry out any work on the fuel supply system, such as changing a solenoid valve, replacing or cleaning a carburettor or even just replacing an old fuel filter, you will need to do an M-Tronic reset.

Secondly, if you find that the saw isn’t running as expected (for example, not revving to its full potential), it is always worth resetting your machine as this may offer a quick and simple resolution.

There are two methods to reset a STIHL machine with M-Tronic. Method 1 is for machines with M-Tronic 2.0 or lower, and Method 2 for Machines with M-Tronic 2.1 or higher. It’s easy to tell which version you have by looking at the CE label. Machines with M-Tronic 2.1 or higher are shown on the label highlighted here. If it’s not shown on the CE label (M2.1 or M3.0) then it is likely you have an older version of M-Tronic.

Method 1 for M-Tronic re-set:

- Remove the scabbard

- Ensure the chain brake is engaged (on)

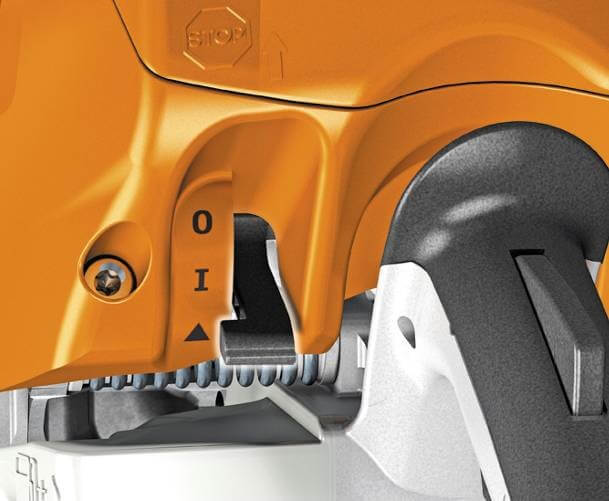

- Put the machine in the ▲ Cold start position

- Start the machine and run it in the ▲ Cold start position for at least 90 seconds

- Do not touch the throttle or accelerate the saw during this time

- After 90 seconds, switch off the machine

- Your machine is now re-calibrated and ready for operation

Method 2 for M-Tronic re-set:

- Remove the scabbard

- Ensure the chain brake is engaged (on)

- Put the machine in the ▲ Cold start position

- Start the machine and run it in the ▲ Cold start position for at least 30 seconds but no more than 60 seconds (the period marked as A in the diagram below)

- Do not touch the throttle or accelerate the saw during this time

- Disengage/release the chain brake

- Open/squeeze the throttle fully for at least 30 seconds (B in the diagram)

- Engine speed varies noticeably during calibration

- As soon as the engine speed drops noticeably (C), release the throttle back to the idle position

- When the engine is back to idle speed, engage the chain brake and switch off

- Your saw is calibrated and ready for operation

Always double check your Owners’ Manual to make sure you are following the right reset procedure – you can find copies of Owners’ Manuals on the STIHL website here.

Always double check your Owners’ Manual to make sure you are following the right reset procedure – you can find copies of Owners’ Manuals on the STIHL website here.

Please note that when using a chainsaw, you should always wear the correct Personal Protective Equipment and take any necessary precautions.

Paul Hicks

Paul Hicks

How should I know which procedure is for my 241 cm saw? Where to look in the manual? Thanks

Hi Boris, you need to follow the first procedure shown above (the one with 6 steps) for an MS 241 C-M. Thanks for reading!

Hi, I cannot do a reset, my ms241 cm dies after 7080 seconds? What should I do?

Hi Boris, thank you for your comment. It’s very hard to diagnose the problem online – we always suggest taking it back to your local STIHL dealer as they have diagnostic software they can use to help work out what the issue is. You can find your nearest dealer here: https://stihlapproveddealer.co.uk/. Thanks, STIHL GB

I have tried the first steps above on Ms 241c, and when I completed and put on the full run the machine doesn’t accelerate and eventually dies (switching off). Need help

Which procedure is correct for ms 261 c-m?

Hi Chris, the first procedure shown above (the one with 6 steps) is the correct one for an MS 261 C-M. Hope that helps!

And how To reset fs490?

Hi Henry, it’s the first procedure above for the FS 490.

Thanks, STIHL GB

I have a Ms 362 c and it won’t start on cold start to do the reset, the saw idles ruff and won’t rev above idle without bogging down so bad you can stop the chain With your hand, I’ve done all I know to do will gladly take any suggestions

Hi Mike, thanks for getting in touch – have you taken it back to a STIHL Approved dealer? It’s hard for us to diagnose issues online, but STIHL dealers are trained on our machines so will be able to help. If you have any issues after that, you can also call our Customer Services team on 01276 417678. Thanks very much, STIHL GB

I have a 441 C. It has a tendency to either be slow to return to idle when throttle is let off, or will rev up without touching the throttle.

Hi Andrew, have you taken it into a local dealer? They will be able to take a look at it for you and should be able to help. If the dealer is unable to help, you can always call our Customer Services Team on 01276 417678, as they will be able to direct queries to our Technical Department.

Thanks very much, STIHL GB

I have some 362 c’s , I also have a new 661. My 362 will not start on cold start and will not idle so I cant reset it so what do I do about that. My 661 will start but when you touch the throttle it dies. I don’t have time to take them to the shop every week is there a computer I can purchase to work on my on saws.

Hi, I’m afraid we don’t sell the diagnostics machines to end users. If it’s still causing issues every week though, it sounds like you haven’t got to the root of the problem. If the dealer hasn’t been able to resolve if for you, you can call our Customer Services team on 01276 417678. They can refer any queries on to our Technical Team. I hope you get it sorted, thanks, STIHL GB

You won’t sell machines to end users so that we have to deal with whatever incompetent people are at our local saw shop?

My 201 won’t idle and I can’t adjust the carb because there is only a plug where there should be adjustments. I can’t run the reset procedure, the folks at the dealer couldn’t even tell me the procedure, and they said they don’t have a machine to plug into it.

I bought a $600 paperweight. Maybe it will have some interchangeable parts with my 2016 201 so it has any use at all for me.

Hi Kyle, this is the blog for STIHL Great Britain, so if you bought your saw in the US, unfortunately we wouldn’t be able to help. But you can contact STIHL USA directly using the contact details on this page: https://www.stihlusa.com/information/corporate/contact-us/ and they should be able to help out. Thanks very much, STIHL GB

My 201 Mtronic is my 15th piece of Stihl equipment. (First was a 020).

Damn thing is worse than a paper weight — it teases me for 4-5 minutes before refusing to start until completely cold.

Manual saws reset by cutting wood. If only I could cut wood…

Climbing a tree with a saw that won’t run after the third limb — what value I received.

Any way to modify to an adjustable carb?

Hi, thanks for your comment. This sounds like an issue with an M-tronic solenoid valve as hot starting can be difficult when the valve is worn by contaminants in the fuel. Please contact a STIHL Approved Dealer who will be able to advise and check the saw, but a solenoid could be the issue here. The MS 201 TC-M made pre mid 2019 was the older reset process, that is, the first one shown above. Thanks very much, STIHL GB

Dude your awesome!! Our shop had ours for 4 mons and still hasn’t fixed or figured out the problem

Hi there, we’re so glad you found this article helpful. However, 4 months is a long time to resolve an issue, unless they are just waiting on parts. You can always contact our customer service team directly if you are experiencing delays by emailing enquiries@stihl.co.uk. Many thanks, STIHL GB

Hey TTS, it’s always worth having a spare solenoid valve. These meter the amount of fuel to the engine (part of all that dynamic calibration goodness that mtronic does). But, if a bit of dirt gets into a solenoid valve, they can block and fail. I’ve just fixed my 661 this way. A defective solenoid does not mean mtronic is inferior in any way. A solenoid valve should be considered to be like any other consumable item on a saw. They are relatively inexpensive to buy and very quick and easy to replace.

There was a lot of negativity around mtronic in the early days, a lot of it unjustified. It is now a mature tech (over 10yrs) and on version 3.0. In my humble opinion, it is awesome. I would never go back to a manual carb. Strat engines plus dynamic electronic fuel metering is huge progress. Like what fuel injection did for our cars. The manual setting of H and L on a manual carb (on a car or a saw) is a static thing, whereas mtronic takes into account many metrics in setting the fuel/air mixture – temp, altitude etc. Probably the main reason I see much less carbon in the combustion chamber when I pull the cylinder head on a saw. Then add to this the lower ash mix oil …

Last point – despite what people say, you can still work on mtronic carbs – replace parts of the cab kit, clean the carb filter. You can also replace a blocked solenoid (the equivalent of spraying carb cleaner down the H&L of a manual carb). I am, of course, referring to saws outside of warranty, otherwise take to dealer, as advised earlier.

Hi i do forestry services with brush cutters fs 560 can you telme how to reset it the carburator or the

m tronic sistem ??

Or can you send number so i can calle n ask about it. Tks

Hello, with an FS 560 brush cutter, you need to follow the first process in the blog above. If you have any further issues, you will need to take it back to your local STIHL approved dealer. I hope that helps, thanks, STIHL GB

Sounds like the m-Tronic system is less reliable than the old fashioned two mix engine.

For occasional agricultural use would a two mix engine be more suitable?

Thanks Ed

Hi Edward, thanks for your comment. The M-Tronic system is designed to give optimum power/performance, and works well for that purpose. In actual terms, apart from ignition timing, there’s actually little difference from a conventional carb engine. However, for occasional farming use, we would recommend one of our agricultural saws, like the MS 271, MS 291 or the MS 391. You can find all of these saws here: https://www.stihl.co.uk/STIHL-Products/Chainsaws-and-Telescopic-Pole-Pruners/0120/Petrol-Chainsaws-for-Agriculture-and-Landscaping.aspx

I hope that helps!

Thanks

STIHL GB

Used my ms261 c yesterday. Was ok. Used it 5mins later. No start. Have fuel but no spark. Changed plug. Will I have to take to a dealer. Has worked faultlessly for 2 years

Hi Mel, thanks for your comment. We always recommend taking a tool back to your STIHL dealer if there are any issues as it’s very difficult to diagnose any problems online. You can find your nearest dealer here: https://stihlapproveddealer.co.uk/

Thanks very much

STIHL GB

Please stop the madness! You make these expensive saws and those of us that use them for a living are fed up with this crap! Please build a saw that we dont have to tinker with everytime we clean the saw out. Please with all your german technology replace M-tronics with a NO TINKER SYSTEM!

Thank You for listening to my rant.

Hi Don, the main aim of the M-Tronic technology is that you don’t have to tinker with the mixture screws. If the saw isn’t performing right, a reset can help but if you are having issues with your saw, we recommend you take it to a STIHL dealer tfor a check-up. Thanks, STIHL GB

Its the inconvenience of having to go to a dealer and not be able to fix myself ,thats the problem.

I had no issues tuning with screws. dealers charge £30 an hour and my nearest is a round trip of two hours. so frustrating if anything goes wrong. I remember this with motorbikes 40 years ago every page in the manuals said “take it to your local Yamaha dealer” give us a chance at self repair.

Hello, thanks for your comment. The idea of this post is to share the information about how to reset the machine yourself, as we do appreciate that lots of users carry out maintenance at home. Thanks very much, STIHL GB

Thanks for sharing information.

My MS 201TC will start and run when using the throttle but as soon as I let it idle it shuts off, sometimes it won’t even start unless I take the air filter off and it’s brand new. Any help would be awesome.

Hi, thanks for getting in touch – have you taken it back to a STIHL Approved dealer? It’s hard for us to diagnose issues online, but STIHL dealers are fully trained on our machines so will be able to help. If you have any issues after that, you can also call our Customer Services team on 01276 417678. Thanks very much, STIHL GB

Hi,

I have a 2016 362c, it starts on cold start when cold and will run at full throttle fine. Once warmed up it isles poorly and will shut down after about 10 seconds idling. Then it won’t start again until it cools down unless you start it with the throttle pulled, ( which is dangerous). I cannot try the first reset on it, the 90 second idling on the could setting as I have to squeeze the throttle to release the switch before I can switch it off, I have tried the second type but it just revs to full throttle once I squeeze the trigger after the initial 30 seconds. I have phoned my local dealer and he says it probably needs a new carburettor, which he said costs about 150 euro and then it’ll need to be fitted. The saw has very little done.. needless to say im not happy..can a standard carb be fitted. Hope you have some advice..

Thanks

Kevin

Hi Kevin, thanks for your message. It’s very hard to diagnose issues with saws on here, so we would always suggest you take it back to a dealer first for them to take a look at. Have they actually had the saw in, or have you just spoken to them on the phone? If you don’t feel that the issue is resolved, could we ask you to give our Customer Service team a call on 01276 417678? They will be able to help or refer you to our Technical department. Thanks very much, STIHL GB

Hi,

I understand the introduction of the electronics. It’s really pretty simple stuff my todays’s standards and can make for a much better product, but it leads to a riduculous situation. There are plenty of people who are capable of stripping/rebuilding a 2 stroke engine to a proper standard but you’ve added the electronics and made the diagnosis dealer-only. Except my dealer has quoted many weeks turnaround time. One way or another this void will be filled – either that or you’ll just start to lose your market share. It’s taken forever to widely publicise the reset/calibrate function etc, but it’s still surrounded by confusion as to how to do individual models.

I’ve bought 5 chainsaws, 2 brushcutters & a hedge trimmer in the last 5 years, all from Stihl, mostly top end pro gear. Plenty of people seek my opinion on what to buy. I can no longer recommend Stihl because of this ludicrous situation. I’ve just bought an Echo chainsaw to try.

If you make your diagnostic software available I’ll become a fan again, but until that happens I’m afraid you’ve lost me as a repeat customer.

Hi, thank you for your comment. We appreciate your concerns, but even with the electronics, it’s still possible to carry out first stage diagnostics on your machines, such as checking the fuel, spark plug, air filter etc. An M-Tronic reset can also be used to recalibrate your tools. If you have a specific issue with one of your tools, please call our Customer Services team on 01276 417678 – they can work with our Technical team to confirm the correct M-Tronic procedure based on the serial number of your machine, and our Technical team can also advise on other early diagnostic steps you can take too. Thanks, STIHL GB

We have a couple of brushcutters fitted with the m tronic system (FS460c-m). What is the procedure for resetting these machines. Thanks

Hi Jon, for the FS 460, you need to follow the first procedure above (the six-step one). We also recommend that you remove the cutting attachment too, when carrying out the M-Tronic reset. Thanks, STIHL GB

Start up procedure for the ms362c?

Hi Bryan

For the MS 362 specifically, the reset procedure will depend on the age of the machine. You will be able to find the full details if you still have the original owner’s manual. If not, then please give our Customer Services team a call on 01276 417678 with the serial number of your machine and they will be able find out the correct procedure from our Technical team. I hope that helps, thanks, STIHL GB

I have 3 ms 201c saws. One I bought 5 years ago still runs great today just the usual wear and tear parts. So I bought 2 more within the last 3 years and I have had both of them in the shop a few times because they melt the side plastic off by the muffler and the bottom of the muffler completely off and really wears out my bars and chains running soo hott my local dealer’s both told me these saws just run hott and just replaced the plastic and muffler and sure enough there doing the same thing again I have heard from others as well that have the same problem. What could be done to resolve the issue hate to just get rid of them these are very expensive saws.

Hi Clint, thanks for your comment. You would be best to talk to our Technical department about this query. If you contact our Customer Services team on 01276 417678, or by email to enquiries@stihl.co.uk, they will be able to put you in touch with someone in the Technical team who will be able to discuss this with you.

Thanks very much, STIHL GB

I have an MS241CM. It’s now about 3 years old and gets a lot of use. I have now replaced the fuel solenoid for the second time, due to the usual problem of failure to restart when warm, then eventually refusing to start at all.

There’s no mention of this fix in the manual, There’s also no mention of the recalibration procedure. Why not?

And by the way, using your reset procedure resulted in refusal to restart once it was stopped after 90 seconds. It appears this was due to a fouled plug caused by running it on a rich mixture for so long. I had to remove and clean the plug; then hold the lever on “off” while cranking a few times to clear the flooded cylinder, then reinstall the plug. Now it’s happier. Surely there’s a more sensible way.

Hi Carl, thanks for your comment. The procedure has been changing with different versions of M-Tronic and different versions of solenoids as we are trying to overcome the issue of dirty fuel making a solenoid wear. Of course, keeping contaminants out of the fuel tank with a clean fuel can is key, but often getting debris in there is going to happen. We have started to add it to manuals of newer saws, such as MS 400/ 500i/ MS 462 etc. For the MS 241-CM, the correct reset procedure is the first one shown above. Often if a saw does run rich (in this case from the solenoid not closing fully), a plug may need to be cleaned. Thanks, STIHL GB

I have a t s 500 i thats got a no spark condition… hooking to m tron dosent give me any results

Hi, thanks for your comment. It’s really hard for us to diagnose technical issues online. Have you taken it back to your STIHL dealer? They would be the best people to look at it in the first instance. Thanks very much, STIHL GB

My MS261C will not reset. I can start it but will only idle in start position for 30 seconds and die and then will not restart. Once before I had a problem and was told to start in start position and idle for 90 seconds and stop. Then start in start position and flip to run for 90 seconds and stop. Then start in run and make five uniform cuts and the saw would be recalibrated. Now I can’t get it to run for 30 seconds before it dies and will not restart. Whats up?

Hi Frank, thanks for your message. It sounds like there is something else wrong with the saw here but it’s really hard for us to diagnose problems like this online. We always suggest taking your tools to your local STIHL dealer as they have the machines to diagnose problems, so please do try that in the first instance. If they can’t help they can always speak to our Technical team for further assistance, or you can give our Customer Services team a call on 01276 417678. Thanks, STIHL GB

Hi which one should I use for MS 500 i /MS 362 cm /ms 462 cm /FS 460cem &FS 490 Cem

cheers

Hi, thanks for your comment. For those machines, you need to use the following procedures:

MS 500i: New procedure (second one shown above)

MS 362 C-M: This will depend when it was made.

MS 462 C-M: New procedure

FS 460 C-EM: Old procedure (first one shown above)

FS 490 C-EM: Old procedure

I hope that helps, thanks, STIHL GB

Hi ms 500i has no cold start, is it still the new procedure but without putting in cold start position?

Hi Ceri, thanks for your comment. Yes, it is just the new procedure but just with the machine running as normal. Thanks very much, STIHL GB

hi,

How do i reset MS201TC ? First or Second ?

I check the user manual this inf is not there…..:

https://www.stihl.co.uk/owners-manuals-safety-brochures.aspx?Search=MS+201+TC-M

Hi, thank you for your comment. For the MS 201 TC, it depends on which version you have, so can I suggest that you get in touch with our Customer Service team as they can speak to our technical experts and confirm the correct procedure. If you drop a message to enquiries@stihl.co.uk confirming the serial number of the machine, they will be able to help. Thanks, STIHL GB

I have a MS661 and it is the biggest piece of junk I have owned! Replaced solenoid valve twice and still bogs out on a twig.Reset after reset tried everything.Costing me nothing but time.GO HUSKY.Mtronic is junk

Hi Scott, I’m sorry to hear of your experience. Have you spoken to our Customer Services team about this? They can refer you to our technical specialists who might be able to help resolve the problem for you. Please do give them a call on 01276 417678 or drop them an email to enquiries@stihl.co.uk and let them know about your issues, including details of which dealer has been carrying out any repair work. Thanks very much, STIHL GB

Hello,

I have a MS 362C from feb 2015. Which procedure should I use?

Thank you

Hi Kim, we think it is likely to be the first procedure shown above, but you should be able to tell from the label on the saw. Machines that have use the second procedure above will have the code M2.1 (or a higher number) on the CE label. Thanks, STIHL GB

Where can I find the CE label on a MS 362C from feb 2015?

Hi Kim, it can typically be found on the front hand guard, although if it’s an older saw, it’s possible it may have come off. If that’s the case, then it is very likely it’s the first procedure above that is needed. Hope that helps, thanks, STIHL GB

Just did an exhaust mod to my 261-cm. After performing exhaust mod, I performed the reset function with the saw. I followed the instructions that were provided in my owners manual and I must say, this saw SCREAMS!!! LOVE IT!! Can’t get enough of this saw!!! I find myself looking for things to cut down. Great saw, great functions, love the learn procedure as once completed you know your saw is set properly. Thanks Stihl!!

Thanks for the great feedback – we love hearing from real STIHL owners! Thanks, STIHL GB

Do you have to do this calibration everytime you start the saw for use?

Hi Steve, thanks for your comment. No you don’t – you only need to do it if you change a component such as carb or solenoid. Alternatively, if you have a running issue, it’s also worth trying an M-Tronic reset to see if that will fix it. Thanks, STIHL GB

Hi, I also have a 500i but with the chain break on it wont run for long enough on idle (no more than 10 seconds) before cutting out. When chain break is off the chain rotates very fast on idle but only after a tap of the throttle first. Not sure how I can perform a reset in this situation when it needs to sit in idle for at least 30 seconds. Any suggestions please?

Hi, thank you for your comment and sorry to hear about the issues you are having. I’m afraid this issue needs to be properly diagnosed though, so the best option would be to take it back to your local STIHL dealer. Thanks, STIHL GB

Hi, I have an ms362c serial number 186018361 Which calibration method should I use?

Hi, thank you for your comment. It’s the second procedure in the blog post that is needed for your machine. Thanks, STIHL GB

Hi. I have two Mtronic saws, a MS 201CM V3 and a MS 261V2(?). How am I supposed to start them when they get vapor locked? I normally would choke and pull, but I can’t control the choke. And sometimes (when hot) they act Like they flood. I can start them in run with WOT. Is this flooding or something else?

Hi, I’m sorry to hear about the issues you are having. I’ve checked in with our technical team here and they have said that with the possible flooding and starting problems, they recommend that you take the machines to a STIHL Approved dealer for them to check and diagnose, and repair if necessary. Thanks, STIHL GB

Ms661 once warmed up had a very high idle and takes along time for it to idle down and before the chain actually stops, I performed the m-tropics resets with no luck of changing anything, any suggestions

Hi, thank you for your comment. Have you spoken to a STIHL Approved Dealer about it? They are trained to diagnose and repair any issues on STIHL products so they should definitely be your first port of call. If you have spoken to them and need further information, please can I ask you to get in touch with our Customer Services team who will be able to put you in touch with a Technical expert to talk it through. You can contact them via email on enquiries@stihl.co.uk or by phone on 01276 20202. Thanks, STIHL GB

Is the procedure the same for brushcutters? I have a FS-460 from 2020.

Hi, thanks for your comment. Yes, it is the same procedure for brushcutters. Thanks, STIHL GB

Hi . 2 years ago my brand new ms661c was stolen. Thankfully I registered the serial number and the police returned it . Unfortunately the plug wire was pulled out and a few minor parts were missing. I tried to replace the plug and reconnect the wire but it won’t start . Can you reccomend a shop that can really just give it a go over because I am afraid to do any damage or have future safety issues . Thanks

Hi, thanks for your comment. The best option is to take it to any STIHL Approved Dealer and they should be able to help. If there is anything they are concerned about, they can also get in touch directly with our Technical team for additional support. Thanks, STIHL GB

Holy Crap! Used method 1 and it worked! I am a tree climber and have the ms201TC so it kep dying after every cut to the point it was dangerous having reach across my riggings to restart. I bought the saw in Washington State (sea level) then was using it at 6800 elevation in New Mexico. This resolved the problem…Thanks!

Thanks for the feedback, glad to hear you have managed to resolve the problem. Thanks, STIHL GB

Hi !

I have MS 201 C-M. I’m using the method 2 for calibration.

It never reaches the phase C ie. engine speed doesn’t come down unless I released the throttle myself.

Does this indicate any failure ?

I’m asking because I’m having a problem that engine stops after minute or two. Starts again with choke and stops again after about same time, and again and again. Calibration seems to help for a while but then problem starts again.

Stihl service calibrated the saw and it helped some time but didn’t fix the problem.

So far tank valve, fuel filter, air filter and solenoid have been changed.

Hi, thanks for your comment. We would consider this unusual behaviour for MS 201 C-Ms manufactured after 2018. If a STIHL dealer has already performed an M-Tronic reset and solenoid valve change it’s possible the running issues are not related to M-Tronic. We recommend taking the saw back to your STIHL Approved dealer who should be able to diagnose the issue for you. Thanks, STIHL GB

Thanks for the answer STIHL GB !

I was reading manual found from the net by keyword MS 201 C-M, not taking account the manufacturing year. Now after your comment I checked the time. Actually, my saw is made on 2016. I also found the original paper manual and it doesn’t say anything about the calibration.

So, should I use the method 1 ?

BR

Esko

Hi, thanks for your comment. Yes, you should be using method 1. There is also a video on the STIHL GB YouTube channel, which explains the process: https://www.youtube.com/watch?v=ccI8yEAjTMg

Thanks, STIHL GB

Hi! I have an MS500i and i can’t make the reset. I followed the instructions of the method 2 (engage chain break – start the chainsaw and let it idle for 30-60 seconds – disengage the chain brake – squeeze the throttle fully for at least 30 seconds) but the engine speed didn’t varies noticeably as reported in the diagram during the phase B, rather it remained steady at max rpms and there’ wasn’t a noticeably speed drop down (phase C in the diagram). Problably I’m missing something during the procedure…so, are you sure that the method 2 (without having to connect the chainsaw to diagnostic tool/software) is valid also for the MS500i ??

Best regards

Fred

Hi, thanks for your comment. The MS 500i chainsaw doesn’t feature M-Tronic technology, instead it uses fuel injection. As a result the reset methods on this page don’t apply. If you are having other issues with your saw, we recommend taking it to your nearest STIHL Approved Dealer. Thanks, STIHL GB

How can the m-tronik version be determined from the number of the control unit? Because, for example, they were replaced.

Hi, thanks for your comment. Control modules have to be replaced like for like, so the M-Tronic version will still be the same as the one listed on the label on the machine. Thanks, STIHL GB

Na minha opinião tem um erro no procedimento orientado pela stihl, exemplo as ms 362 versão 2.0 pede para deixar em marcha lenta por no mínimo 90 segundos e desligar sem tocar no acelerador. Gostaria de saber como desligar sem tocar no acelerador já que a chave desliga não vai da posição partida frio para posição off sem tocar no acelerador. Ela fica travada impossível desligar sem dar um toque no acelerador. Gostaria de um esclarecimento

Hi Oscar, thank you for your comment. When calibrating the M Tronic carburettor on an MS 362, the user must let the saw idle for 90 seconds and then turn off without touching the throttle. Pushing firmly on the Switch Shaft upwards will cause the machine to switch off. If the throttle trigger is depressed it will not allow the M Tronic carburettor to calibrate/reset. Please note, the switch shaft is designed to withstand the extra force required during this process. Thanks, STIHL GB.

I have ms441m 11/16 really difficult to start do I use method one to reset

Hi Terry, thank you for the question. Yes, the MS 441-CM requires method 1, however it’s unlikely that a reset will fix the starting difficulties. Providing that all other components are in good condition (filters, spark plug etc) then a new solenoid valve could be the solution. A STIHL Approved Dealer would be able to investigate this for you and complete the repair. Many thanks, STIHL GB.

Hi. After recalibration, my “MS 261 C” still does not respond right away when the throttle is pressed. There’s a noticable lag. It feels similar to the way the old adjustable saws used to run when the “H” or “L” setting was off!

Any suggestions? Thank you.

Jes

Hi Jes, there are a lot of variables that could cause an issue like this so your best option would be to take your chainsaw to a STIHL Approved Dealer to have a look at in person. You can find your nearest one using our dealer locator https://shop.stihl.co.uk/pages/dealer-locator

Many thanks, STIHL GB